The current economic environment is incoherent and unpredictable, and the gap between available labor and expected growth grows wider every day.

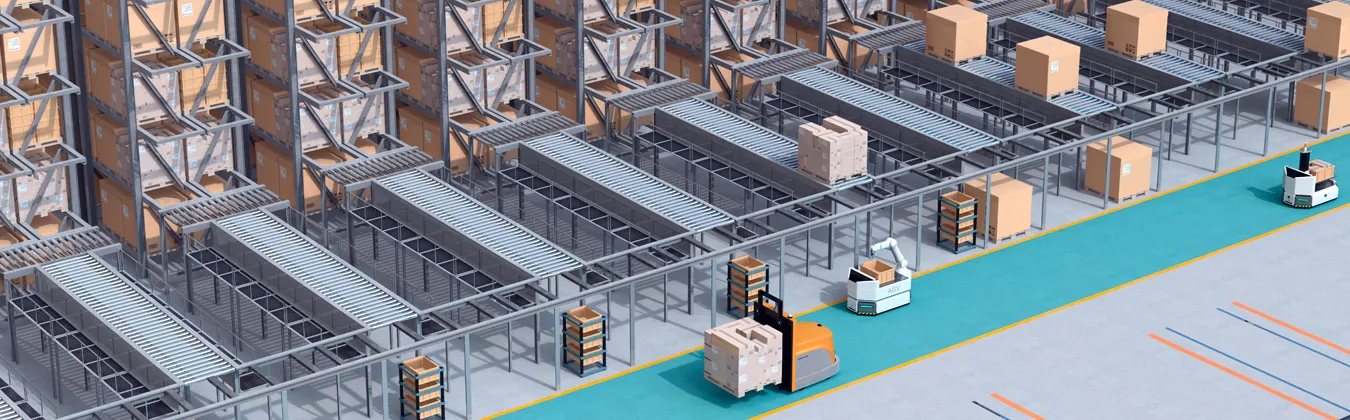

A pivot in consumer behavior toward eCommerce seems to have led to a noteworthy overhaul of supply chain management processes. The traditional business model—with its focus on shipping bulk to stores and distribution centers—has been disrupted by eCommerce, requiring adjustments in operational structures and labor requirements. Warehousing has taken on a new role with much more expansive and complex operations.

The eCommerce market in the United States is set to reach over $1.1 trillion in 2023. By 2026, the global eCommerce market is predicted to exceed an astounding $8.1 trillion. With skyrocketing demand and a persistent labor shortage, warehousing operations must lean on automation solutions and technology to keep up. Cutting-edge technologies such as AI, drones, robotics, the Internet of Things (IoT), and Augmented Reality (AR) can guide you on a competitive path into the coming years.

Currently, at $22.15 billion (2023), the warehouse automation market is projected to expand at a CAGR of 16.20% to $46.93 billion by 2028. The numbers and trends all seem to point in the same direction: warehouse automation solutions are the future.

Warehouse Automation Trends

Persistent labor shortages have accelerated the adoption of many warehouse automation solutions. To keep up with a booming eCommerce market, warehouses and distribution centers should consider leveraging modern technology to meet customer demand. However, a perceived financial barrier to adopting such technologies has kept many operators from investing.

While these technologies can be a significant financial investment, the long-term ROI is far greater than working solely with human labor. Once you shift your thinking from short-term ROI to long-term improvement, the benefits become obvious.

-

Robotics in Warehouse Operations

The warehousing industry leaned on robotics well before the current labor shortages. eCommerce exploded over the past decade, forcing players like Amazon and FedEx to pivot towards automation.

For example, consider Amazon’s acquisition of Kiva Systems in 2012. The Massachusetts-based robotics company specializes in autonomous mobile robots (AMRs), which work alongside human laborers to move heavy shelves of goods around the warehouse. Meanwhile, FedEx partnered with Vecna Robotics (also out of Massachusetts), deploying their AMRs in warehouses around the United States.

Before the pandemic, most warehouse robots performed tasks with little variation. They could move objects from A to B, but couldn't complete the more complex tasks of their human counterparts. Developers’ focus now is mostly on creating systems that can circumvent this problem, manipulating objects of complex shapes and sizes. These new automation solutions must adapt to unpredictable warehouse circumstances, leveraging modern AI technology to learn as they go.

Robots most likely won't replace your workforce. But they can work alongside humans, performing more dangerous and monotonous tasks while human laborers focus on the meticulous. For example, Collaborative Robots, or Co-Bots, can work alongside human pickers to transport items around the warehouse.

Robotic arms have also come a long way since early applications in manufacturing. Enhanced vision systems and gripper capabilities allow modern robotic arms to perform more particular tasks. They're often perfect for repetitive actions like packaging, picking, placing, and sorting.

-

Increasing Inventory Efficiency with Drones

Drones are no longer just reserved for hobbyists. They've found a home in several industries, from agriculture to real estate. For example, AI-powered drones have helped change the way we look at inventory management and security in the warehouse. With a camera, scanners, and the right processing power, these drones can completely overhaul your current inventory management systems.

Think about what happens when you order something online. Someone in the warehouse has to find and retrieve the item, and these warehouses—think of Amazon's massive fulfillment centers—can be upwards of 3 million square feet. What if that item is high on a shelf? The worker must go back, get a lift, and return to grab the package.

Drones streamline the inventory management process. They know where every item is in the warehouse and can direct workers for retrieval. Instead of your human workforce scanning every barcode on the shelf—a task that may take all day—drones can scan them in a few hours. Furthermore, drones make the warehouse safer, as humans don't have to scan items on the top shelves.

Aside from inventory management, drones can also provide heightened security. Companies can turn to drones to keep an extra set of eyes on their warehouses 24/7—as these machines don't need to eat or sleep. Instead of paying several security guards to roam the warehouse and perimeter, one can monitor the drones’ video feeds.

-

The Internet-of-Things (IoT) Enhances Warehouse Management

It's no secret that IoT has helped revolutionize the way businesses run. The global IoT in warehouse management market is expected to increase from $12.13 billion in 2023 to $28.79 billion by 2030, exhibiting a CAGR of 13.1%.

Modern IoT technology provides one of the best options for optimizing warehouse management. These warehouse automation solutions can streamline your inventory management system, effectively building a “smart warehouse” that leans on AI and automation.

With IoT solutions, warehousing professionals can capitalize on:

- Automation. Automatically confirms shipping and service tracking, allowing inventory managers to focus on less time-consuming tasks.

- Asset tracking and management. Manage location, transportation, packing, and shipping data in real time.

- Inventory optimization. Get the most out of your available warehouse space and decrease time spent locating inventory around the warehouse.

- Predictive maintenance. IoT sensors can monitor warehouse equipment and leverage machine learning to prevent breakdowns.

-

Artificial Intelligence (AI) Makes Warehouse Automation Smarter

Artificial Intelligence (AI) can serve as the brain of your operation. It links all your warehouse automation solutions together, ensuring that they maximize efficiency. Drones, robots, and IoT technology all rely on this central network to navigate the warehouse and perform their assigned duties; AI also aids human laborers in bolstering safety and efficiency around the warehouse.

AI can help design safer, smarter layouts for the entire warehouse. According to the latest (2023) BLS and CDC statistics, roughly four in every 100 full-time warehouse employees will suffer an injury at some point. Amid persistent labor shortages, warehouse operators can't afford to lose a single one of these workers.

AI leverages data to understand how workers use the warehouse, where employees gather, and where the potential for injury exists. Then, it compiles the data to suggest optimized warehouse designs for maximum safety and efficiency.

Humans can also leverage voice assistance AI technology to perform tasks around the warehouse. Employees can tell an AMR to retrieve specific items from around the warehouse with just a few words—order picking can be as easy as talking into a microphone.

-

Better Visibility Across Warehouse Processes Using Augmented Reality (AR)

One of the valuable things about augmented reality (AR) technology is its easy accessibility for inventory management. AR uses your phone or tablet camera to scan objects in the frame. Then, it uses available data to provide more detailed information about what you're looking at—often rendering items in 3D format.

Warehouses are vast landscapes with hundreds of thousands of items. AR can understand the warehouse layout, every item within, and where to locate those items. Then, it can create an optimized map of sorts to guide workers to the items they need. Arrows appear in AR, and workers can follow them to a destination. The item will even appear on-screen, providing workers with necessary information.

However, the applications of AR often go far beyond scanning inventory. AR can bolster employee training by pairing with more familiar technologies, especially for younger generations. AR also helps you envision warehouse upgrades before breaking ground, giving insight into layout and traffic flow planning.

Costs of Automating Warehouse Management and Operations

Modern warehouse automation solutions can change the way you do business. The question these days is less “how will this technology help?” and more “how much will it cost?” Your bottom line is one of the most important parts of running a business. While you want to capitalize on a booming eCommerce market, you should consider long-term ROI before investing in automation.

The cost of an automation system depends on how far you're willing to go. On the low end, it could cost between $500,000 to $1 million to implement basic warehouse automation solutions like picking robots. On the high end, you might run a bill upwards of $25 million to turn your warehouse into a fully automated and innovative facility.

Because these costs are so steep, consider taking gradual steps toward complete automation. Identify the areas of your business that could benefit most.

To calculate your ROI, determine what types of software and hardware solutions you want to apply. Then, calculate the estimated budget for your current warehouse operations, including labor and existing equipment. You must also factor in your average turnover rate and the cost of hiring/training new employees.

Finally, determine the types of warehouse automation solutions you're looking to invest in and how/where they'll save money on labor and maintenance while boosting efficiency and productivity. You can calculate your automation ROI with all this data in hand.

Factors to Consider When Implementing Warehouse Automation Solutions

With so many different automation solutions available, carefully assess what will benefit your particular warehouse. Everyone’s needs differ; what works for a different company may not help you as much.

In general, automation proves best for time-consuming, repetitive, process-oriented, and error-prone actions. Consider which warehouse tasks fall into these categories and how automating them will be better for business. Once you've identified these areas, you can take the following steps toward automating your warehouse.

First, seek advice from industry experts, both on the installation and financial sides. These automated systems need to integrate into your current processes. While that may prove easier for smaller systems like drones, large-scale automative overhauls require integration experts who will incur additional expenses. On the financial side, a financial partner can help you determine how to strategically fund your capital investment and its potential impact on your cashflow and overall profitability.

Business owners should also take into account the type of warehouse operation being considered for automation: dedicated, shared, or integrated omnichannel.

- Dedicated warehouses are designed for a specific channel, product flow, or product type. These types of warehouses look to leverage automated practices to address scale and cost efficiency.

- Shared warehouses service multiple channels, such as wholesale and direct-to-customer (DTC). They also entail perishable products, making them most popular in agriculture. Because of their shared nature, these warehouses can leverage technology to support specific flows and order profiles between channels. Still, they can leverage AMRs and other automated solutions to address more labor-intensive tasks.

- Integrated omnichannel warehouses address all channels seamlessly, leveraging technology systems to manage inventory across a common stock pool. Omnichannel facilities generally offer the most flexibility, although operators may have to make sacrifices on cycle time, productivity, and dedicated capacity.

Facing an ever-changing market, many warehouse operators are pivoting away from turnkey providers, and towards as-a-service warehouse automation solutions. Investing in robotics-as-a-service and fulfillment-as-a-service can help circumvent hurdles associated with up-front financial risk. Now, operators can play with a variable cost structure to test and learn more about emerging technologies and how they can help their warehousing operation.

Take Your Warehouse Operations Into the Future

Warehouse automation solutions can lead the way for business owners to combat labor shortages while meeting exploding eCommerce demands. However, adopting new technology isn't as easy as just ordering it online. Large warehouses require meticulous planning and financial consideration before making such an investment.

Partnering with a trusted financial institution can help you prepare financially for big moves. Contact Premier Valley Bank, a division of HTLF Bank to speak with a commercial banker and carry your operations into an automated future.

These links are being provided as a convenience and for informational purposes only; they do not constitute an endorsement or an approval by HTLF of any of the products, services, or opinions of the corporation or organization or individual. HTLF bears no responsibility for the accuracy, legality or content of the external site or for that of the subsequent links. Contact the external site with questions regarding its content and privacy policy.